The ALPLA Story: Technical challenges and the Alplamat

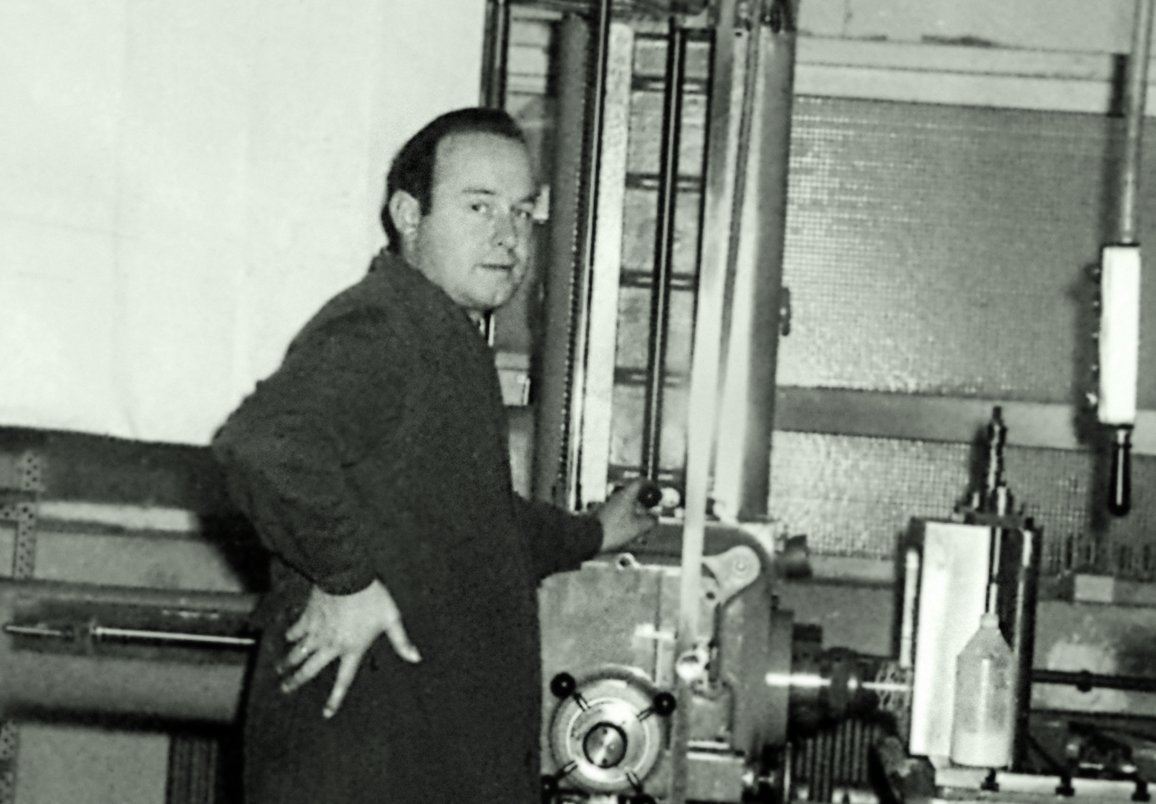

Alwin Lehner at his boring mill around 1960.

Our blog series The ALPLA Story provides insights into how ALPLA became the company it is today. In part I, The ALPLA Story: From Christmas trees to the first big order, we explored why the brothers Alwin and Helmuth Lehner decided to establish a packaging company and their first business venture. Since the publication of part I, we have sadly had to say goodbye to Alwin Lehner, who passed away at the age of 86. Alwin Lehner was always interested in and passionate about technical challenges and was the innovative force at ALPLA at the beginning. In part II, we will learn more about his first foray into technical developments and the initial growth of the company.

After just one year of business, the investment in an injection-moulding machine by Battenfeld, a renowned maker of injection-moulding equipment, had paid for itself – Alwin could finally give up his second job. Soon, the Lehner family needed support with the handling of incoming orders and hired additional employees. This also meant that space was getting tight, which is why they decided to extend the parental home that they had been producing in.

Plastic was not such a big part of our daily lives at the beginning of the 20th century as it is today. After the war, in the 1950s, plastic was slowly getting more popular. Due to the scepticism concerning plastic before, the processing and machinery for the material was not particularly advanced. Therefore, the brothers had to experiment and carry out a lot of tests to find their way. It was challenging and time-consuming.

In 1958, ALPLA began producing bottles for a glass cleaner, which marked a turning point from pure injection moulding to cutting-edge blow-moulding technology. Then, with the production of its first polyethylene plastic bottles, the young packaging company encountered considerable problems. With the granules then in use, the new blow-moulding equipment was not operating as it should have. At first, Alwin confined his efforts to developing tools of his own to use with the machinery to improve production results. But soon, newly developed plastic materials challenged the limits of the technology in place.

Being the tinkerer that he was, Alwin decided to develop equipment of his own – this marked the birth of the famous Alplamat. In its first incarnation, this semi-automatic machine operated with rudimentary tools and pneumatic controls and was capable of producing bottles in a range of sizes. With this equipment, the company was able to make considerable headway. In the 1960s, he developed the Alplamat even further and added a hydraulic control system. The design was so much ahead of its time that equipment from this continually developing range remained in operation into the 1990s.

And with that, the cornerstone of the company’s technological leadership was laid. The company was continually growing and the Alplamat was introduced to the world. The brothers were still working from their parents’ home with a larger but still fairly small workforce. As we all know, this would not stay this way. We will follow the company’s next step on its way to a multinational company in part III of The ALPLA Story. Stay tuned.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!