ALPLA on the right track with recycling

As a signatory of the Global Commitment (GC), ALPLA has committed itself to a total of six goals. The most important are to process at least 25 percent post-consumer recycled material (PCR) by 2025 and to offer only fully recyclable packaging solutions. To this end, 50 million euros will be invested each year. An interim status of the global goals.

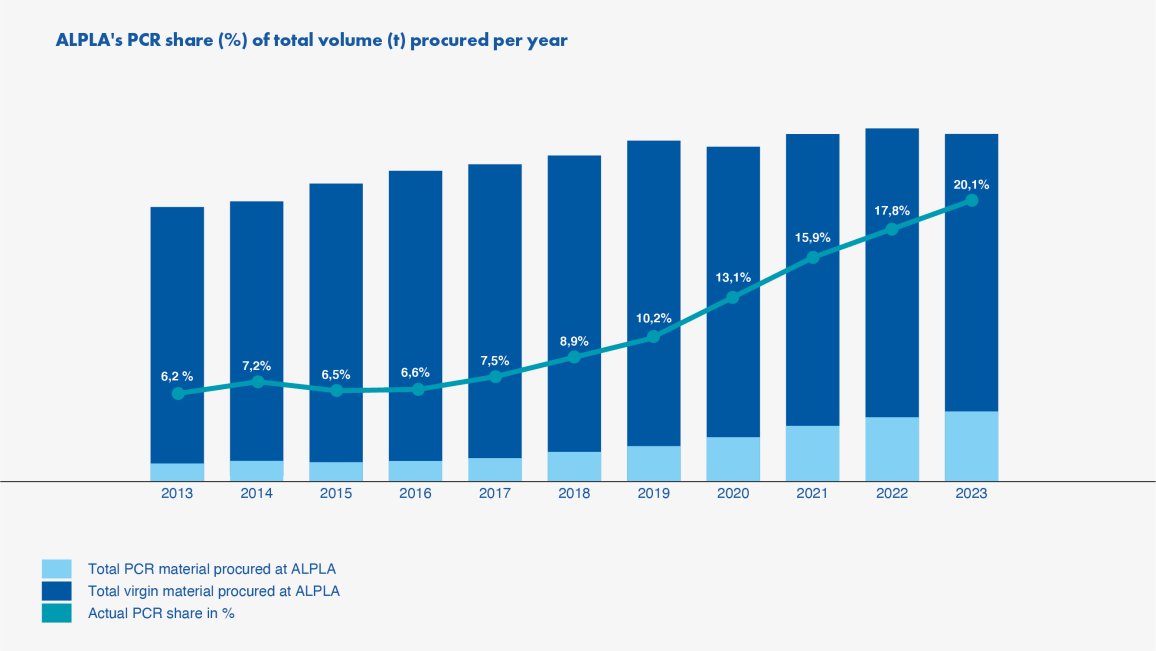

Increasing share of PCR at ALPLA

ALPLA is committed to the circular economy: since 2018, the packaging and recycling specialist has more than doubled the proportion of recycled material from around 9% to 20%. The global average is to be increased by a further 5 percentage points by 2025. By then, a quarter of all material requirements should be covered by recycled plastic. The international company set itself this very ambitious industry-wide target six years ago when it joined the Global Commitment (GC), an initiative of the Ellen MacArthur Foundation in cooperation with the UN Environment Programme.

ALPLA is already further ahead in Europe and North America. In 2023, more than 28% of the material processed there came from the plastics cycle – with an upward trend. Increasing the proportion of PCR in the overall product portfolio is just one part of the global commitment. By 2025, all packaging solutions should also be fully recyclable. With an average of around 90% for all packaging solutions, ALPLA is well on the way. Also formulated in the Global Commitment and a matter of course for ALPLA: all packaging solutions will remain completely PVC-free.

Solutions for the circular economy

Design for recycling and lightweighting reduce material consumption despite increasing quantities. As a further goal of the GC, ALPLA is working with customers from 2018 to develop at least three additional packaging solutions with significantly reduced weight each year. Pioneering projects such as reusable PET bottles made from 100% PCR material, mono-material packaging and the accelerated recycling of former household waste from the Yellow Bag set the tone in the market and show what is feasible.

ALPLA invests around 50 million euros in recycling every year. With state-of-the-art recycling plants and optimised processes, ALPLA itself provides high-quality PET and HDPE recycling material (rPET and rHDPE) in the ALPLArecycling division. The installed and projected output capacity is now 350,000 tonnes - almost three times as much as the 130,000 tonnes planned for 2025 in the Global Commitment.

Big CO2 savings

Thanks to renewable energy, cutting-edge technology and regional cycles, the company's own recycled material has a significantly lower carbon footprint as compared to the global average for recycled material. It is 59% lower for rPET and 49% lower for rHDPE. Compared to the global averages for virgin PET and HDPE, ALPLA's recycled material saves 88% (rPET) and 87% (rHDPE). In addition to technological expertise in development and production, ALPLA provides manufacturers other good reasons for switching to sustainable alternatives.

The progress report of ALPLA and all other signatories of the GC on recycling can be viewed online at any time (status 2022): https://gc-data.emf.org/2023/ppu/.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!