Turning old into new

The history of packaging - Part Four

The history of recycling goes back as far as packaging itself. But its significance has increased rapidly as populations have grown, prosperity has risen and natural resources have increasingly come under threat. We now face the challenge of evolving away from a throwaway society in the direction of a circular society.

Historically, recycling has primarily been driven by cost-effectiveness and scarcity. Metals and glass were already being collected, melted down and reused in the classical era as demonstrated by, for example, research conducted in the Mediterranean by Austrian scientists. This was economically motivated – raw materials were costly so informal collection was used as a recycling source. Ceramic, which was used to make, among other things, amphoras, could not be recycled, so even back then there were already scrapheaps. Waste continued to be industriously collected into the Middle Ages. In archaeological digs, only shards of glass from the 15th century and later are found, as recycling glass was then presumably no longer worthwhile.

The recycling of another important packaging material is likewise already nearly 1,000 years old – when the Imperial Court in Japan lost control of the country, paper production changed from government control to private hands. Here too, reprocessing used paper proved to be economically advantageous. The first documentary evidence of paper recycling therefore dates back to 1031.

Rampant growth

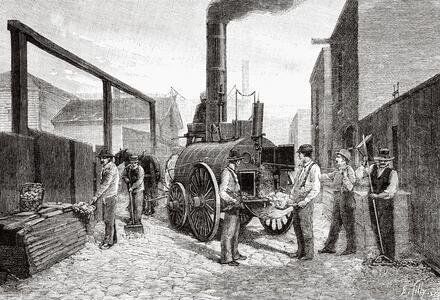

Rapid population growth began some time after 1700. The invention of the steam engine and other machinery led to industrialisation, which in turn resulted in mass production, planting the seed for the throwaway society. Urbanisation took hold and cities grew. In 1804, the global population passed the one billion mark.This led to the first landfill sites and waste incineration plants being developed.But industrial-scale recycling was still in its infancy. In the USA, for example, the first waste sorting facilities were established in New York in 1897 and the first aluminium can recycling plant went into operation in Chicago in 1904.

19th century: Incinerator in Chicago.

Necessity is the mother of invention

War and its consequences have always been drivers of recycling too. During Second World War, for example, church bells were melted down for arms production and construction materials were salvaged from the ruins in order to rebuild destroyed towns and cities. After the war, private consumption was boosted by the Wirtschaftswunder (economic miracle). Supermarkets emerged, resulting in the need for individually and hygienically wrapped produce. In the USA, the magazine LIFE celebrated the new age with a story on ‘throwaway living’. Raw materials and energy were cheap, so campaigns promoting disposable goods were launched, such as the German glass industry’s ‘Ex und Hopp’ campaign. Many reuse systems were discontinued and bottles ended up in the rubbish bin.

Crisis and a rethink

The environmental movement dates back to the 1960s. 1970 was declared European Conservation Year and was also the year in which the globally recognised recycling symbol was created.The Club of Rome published its study ‘The Limits to Growth’ in 1972 and just a year later the first oil crisis forced people to tighten their belts.Large-scale waste management began with paper and glass collection.The debate surrounding forest dieback in the early 1980s helped to raise people’s awareness. The term ‘sustainability’ has its origins in forestry too and had already been around for 270 years by then.

With the introduction of the Green Dot as a symbol of the dual system, responsibility for collecting packaging in Germany and Austria shifted in the early 1990s from the municipalities to industry. This also includes an obligation to recycle.

Our recycling plant in Venta di Banos, Spain.

Status Quo

The following remarks are taken from the Austrian Federal Ministry of the Environment’s ‘Inventory of waste management in Austria’ status report. According to the report, there were 1.41 million tonnes of packaging waste in Austria in 2018, of which 41.7 per cent were paper/card/cardboard packaging, 21.4 per cent plastic, 20.6 per cent glass and 4.5 per cent metal.

- Household paper, card and cardboard packaging end up in paper banks. Waste paper is used for producing toilet paper, newspapers, forms and packaging made of paper, paperboard, card and corrugated board. The paper, card and paperboard used can be put through production and recycling multiple times and is used on average six times. Fibres which are too short are separated out of the production process together with ink residues and other contaminants.

- More than 80,000 recycling banks for clear and coloured glass are available for the collection of glass packaging. The used glass undergoes a number of sorting processes at the glassworks, with impurities and contaminants being removed. It is then melted down at around 1,600°C together with the glass ingredients silica sand, lime, dolomite and soda and is used in the production of new glass packaging. Used glass accounts for up to 90 per cent of green glass and up to 60 per cent of clear glass.

- Plastic packaging which has been collected is sorted by plastic type and impurities are removed. It is then shredded, washed, dried, melted down and turned into pellets, which are subsequently used as a production raw material. High-quality recycling methods include bottle-to-bottle recycling. Here, used PET bottles are sorted by colour and undergo a special cleaning process before being used to produce new PET drinks bottles. Unsorted packaging plastics can be shredded and agglomerated as coarse particles for the manufacture of easily shaped products such as plates or chutes.

- Metal packaging collected separately is sorted at sorting or shredding plants, with foreign materials and impurities being removed. The sorted metal packaging is fully recycled. Ferrous metals are used as a raw material in steel manufacture. Aluminium packaging is manually sorted or is separated out with the aid of eddy current separators. Aluminium can be reused infinitely without forfeiting its specific properties such as conductivity and mouldability.

Reduce, reuse, recycle

What does the future hold in store? The packaging directives adopted by the European Union in 1994 and 2018 serve among other things to avoid waste and facilitate the transition to a circular economy. They involve binding recycling rates for the member states. There is therefore increased public awareness that packaging needs to be avoided, for example by means of measures to reduce food waste and the introduction of environmentally prudent reuse systems. Additionally, valuable materials need to be systematically recycled on the basis of collection and sorting.

Media

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!