Tin cans and the rise of plastics in packaging

History of Packaging - Part Two

A new era: from the tin can to the revolutionary invention of plastics and the origins of ALPLA.

Can-based consumption with risks

On 25 August 1810, the British merchant Peter Durand from the county of Middlesex submitted a patent for preserving foods in tin cans. This was based on the preservation method developed by Appert in France. In turn, Appert invested his reward in building a canning factory. Food and drinks were now stored durably in metal containers rather than glass. And as practical as the tin can was, it still had its pitfalls – gradual poisoning from the lead used to solder the lids was a common consequence of early can-based consumption.

Oat can exhibited in the Museo da Ipiranga in Sao Paulo, Brazil

The triumph of the tin can

The practical can opener wasn’t invented for another 60 years. Now lead-free and the product of automated manufacture, the tin can began to conquer the world at the beginning of the 20th century. The first tin of tuna appeared in 1909, the first can of drink in November 1933. This proved to be a resounding success: the Gottfried Krueger Brewing Company based in Newark, New Jersey, first sold cans of beer to mark the end of Prohibition. There was a real thirst for this, with more than 200 million units being sold in the first year. The Hawaii Brewing Company was incidentally the first to package beer in an all-aluminium can in 1958.

The early cans had to be opened with an opener that came with the cans and what was known as the cone top even had a crown cork. Then the next revolution came in 1962 with the invention of the lift tab. Just one year later, the inventor Ermal C. Fraze had the improved ‘ring pull’ patented and Daniel Cudzik then wrote beverage history in 1975 with the groundbreaking stay-on tab. There has been ongoing work on resealable solutions for around 15 years now. Be it for beer, energy drinks, dog food, tomato sauce or sardines, the can is now an integral part of our daily consumption. The same goes for aluminium tubes used, for example, for mustard or mayonnaise.

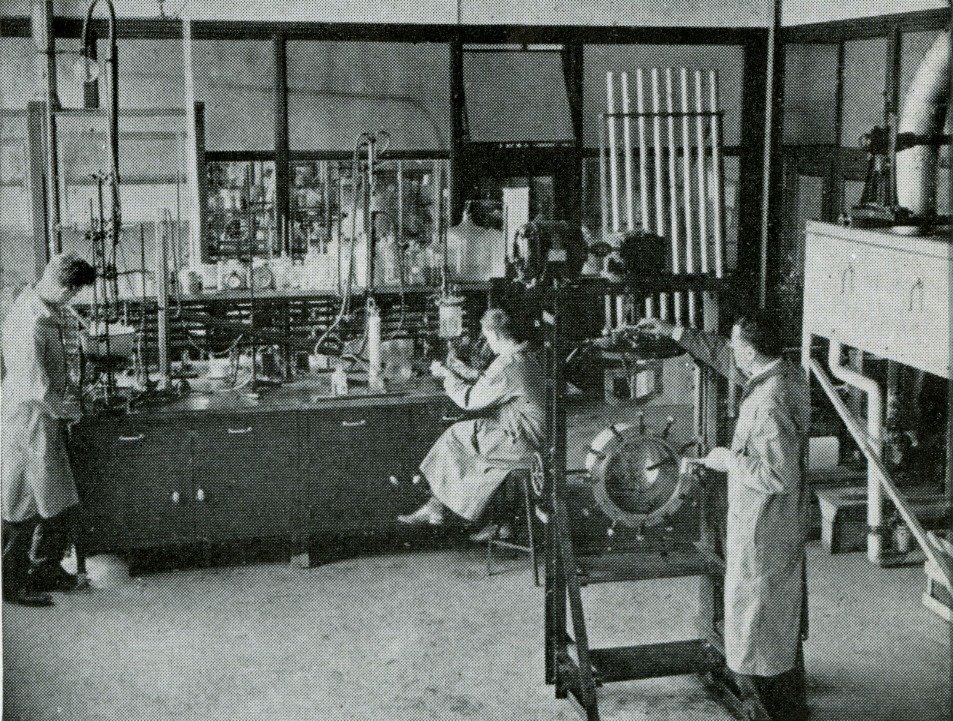

Resin and Varnish Development Laboratory for Bakelit (1935)

Materials from the laboratory

A new era was heralded by plastics in the middle of the 20th century. The foundations were laid for this in the middle of the 19th century with the invention of celluloid, which Alexander Parkes of Birmingham patented in 1856 under the name Parkesine. However, this early thermoplastic was not terribly practical, but this was rectified by the American John Wesley Hyatt, who invented a reliable plastics production method and the world’s first injection moulding machine in 1869.

A discovery made by the French chemist Henri Victor Regnault was just as important – he produced vinyl chloride in 1835. Based on this, the first PVC (polyvinyl chloride) was then developed by Fritz Klatte working at Griesheim-Elektron in Frankfurt am Main in 1912. Five years earlier, Leo Hendrik Baekeland had developed Bakelite as the first synthetic plastic that could be mass-produced. The next thermoplastic material, polyethylene, was then developed by Eric Fawcett and Reginald Oswald Gibson in 1933. Various versions of this are still used to this day, such as those with low (LDPE) or high density (HDPE). At this time, however, plastics were still a niche product and their uncurbed rise only began during the Second World War.

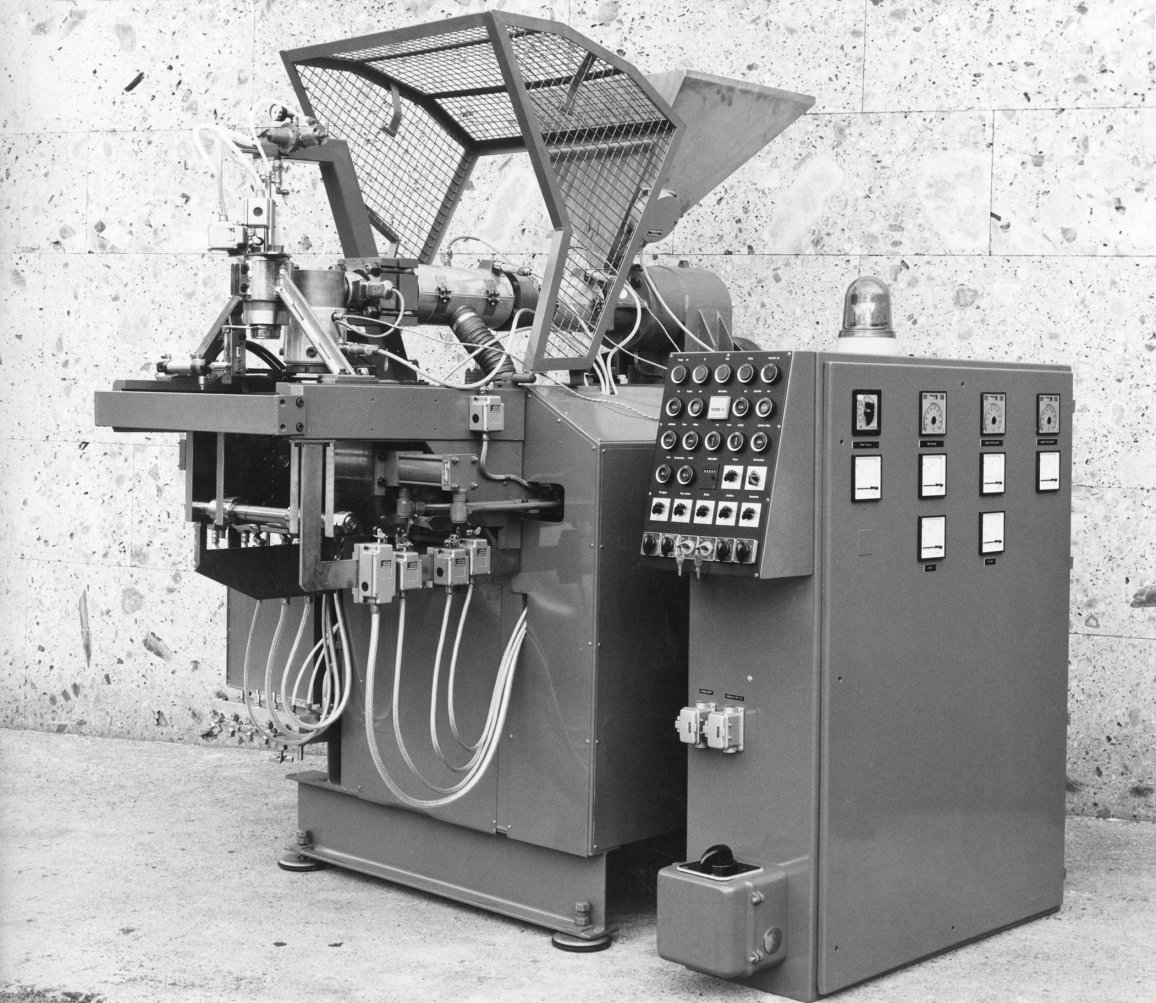

The Alplamat has been one of the first semi-automatic extrusion blow moulding machines

Light and unbreakable – plastics on the rise

Various types of food packaging, drinks bottles and shopping bags were now being produced using PVC and, in particular, polyethylene. This followed major advertising campaigns that proclaimed the many advantages of these new materials. Plastics were light, hygienic, durable and robust – in contrast to glass, metal or ceramic. They were also mouldable – as suggested by the word ‘plastic’, which comes from the ancient Greek for ‘to mould’.

The phenomenal rise of the polymers took its course with the development of the first extrusion blow moulding machines in the 1950s. These allowed plastic bottles and containers to be produced more easily and more quickly. And ALPLA was already a leader in this field back then. Three years after founding the company, Helmuth and Alwin Lehner presented one of the first semi-automatic extrusion blow moulding machines, the legendary Alplamat, in 1958.

Another plastic joined the ranks in 1954 when the Italian Nobel laureate Giulio Natta produced polypropylene (PP). From the 1970s, widespread use for drinks bottles was made of polyethylene terephthalate (PET), which had been developed by John Rex Whinfield and James Tennant Dickson in 1941. The PET bottle was patented by Nathaniel C. Wyeth in 1973. It was not only light and practical, but also and above all recyclable.

The history of recycling began in 1977. Since then, the material, design, production and recycling have been continuously further developed – in particular by ALPLA. The company demonstrated pioneering spirit in 1985, for example, with the world’s first in-house production facility, in other words plastic bottle production right alongside the customer’s bottling plant. And in 1990, the company unveiled the first bottle made of PCR (post-consumer recycled material). Recycling history has continued to be written since then. ALPLA now processes approximately 60,000 tonnes of food-grade rPET a year – and this figure continues to rise.

Coming soon:

It’s all about branding: packaging customisation

Packaging design: how the characteristic shapes, colours and markings of all packaging types came about.

Copyright remarks pictures:

Picture One: José Rosael/Hélio Nobre/Museu Paulista da USP, Creative Commons Attribution-Share Alike 4.0

Picture Two: Public Domain

Picture Three: ALPLA

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!