Challenges ahead for the beverage industry

EU Directive 2019/904 ‘on the reduction of the impact of certain plastic products on the environment’ requires EU member states to roll out tethered bottle caps for a very large number of single-use plastic beverage bottles by no later than July 2024. It also requires European standardisation committees to establish corresponding standards for them. In parallel with this legal change, all EU states are attempting to reduce their amount of plastic packaging waste. Many businesses, governments, organisations and associations have committed to the European Plastics Pact, which involves an absolute weight reduction of effectively 10 per cent by no later than 2025.

Tethered cap from ALPLA

The industry is adopting new, voluntary standards to try to achieve both goals. Cetie is a standardisation organisation which recommends standards for the development of PET bottleneck finishes, and it and its recommendations have an important role. Its GME30.40 data sheet defines specifications and requirements for highly carbonated beverages, while its GME30.37 data sheet does the same for less-carbonated beverages. Both of these standards incorporate the requirements of the EU directive.

In the past, implementing the recommendations took years and resulted in numerous standards. There is now pressure on manufacturers to achieve, as far as possible, both of the goals described above on time by some point in 2024. This might lead to different approaches and therefore a wide range of different neck variants.

This is because the reduction goal can be achieved faster when the bottleneck is made smaller. There are limits to this, however, as not all small necks are compatible with large bottles. At the same time, the neck finishes must fit the new tethered caps and be adapted accordingly, which subsequently increases the options for solutions. Consumer safety is also important in this context because carbonated beverages are kept at a very high pressure, and that means the closure area requires special attention.

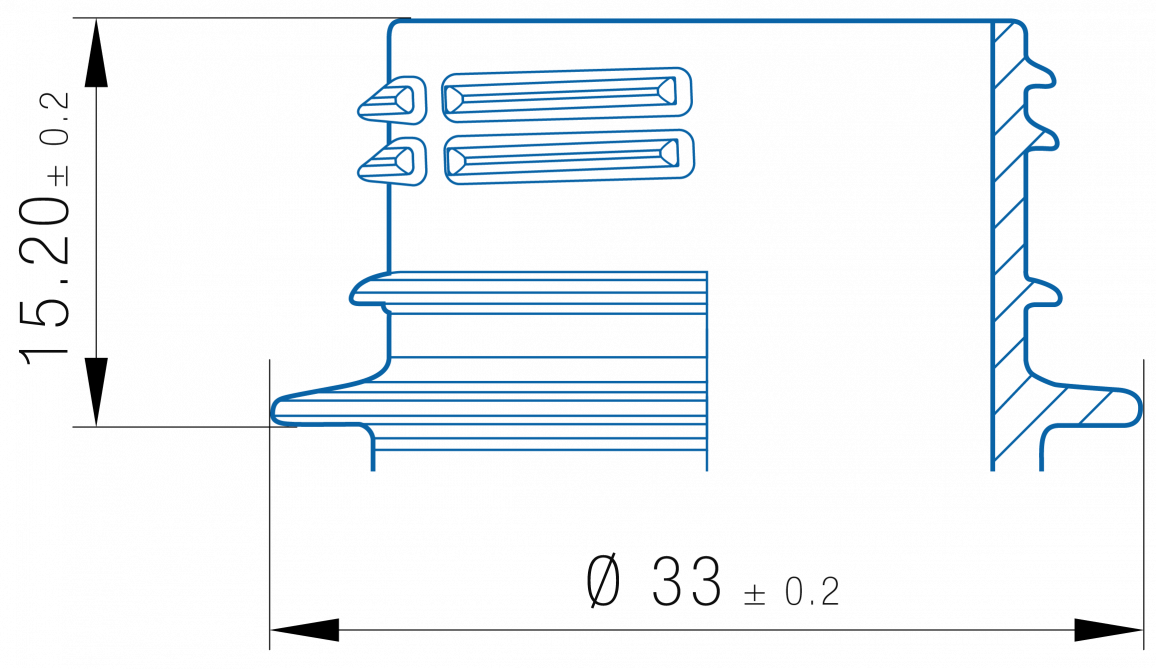

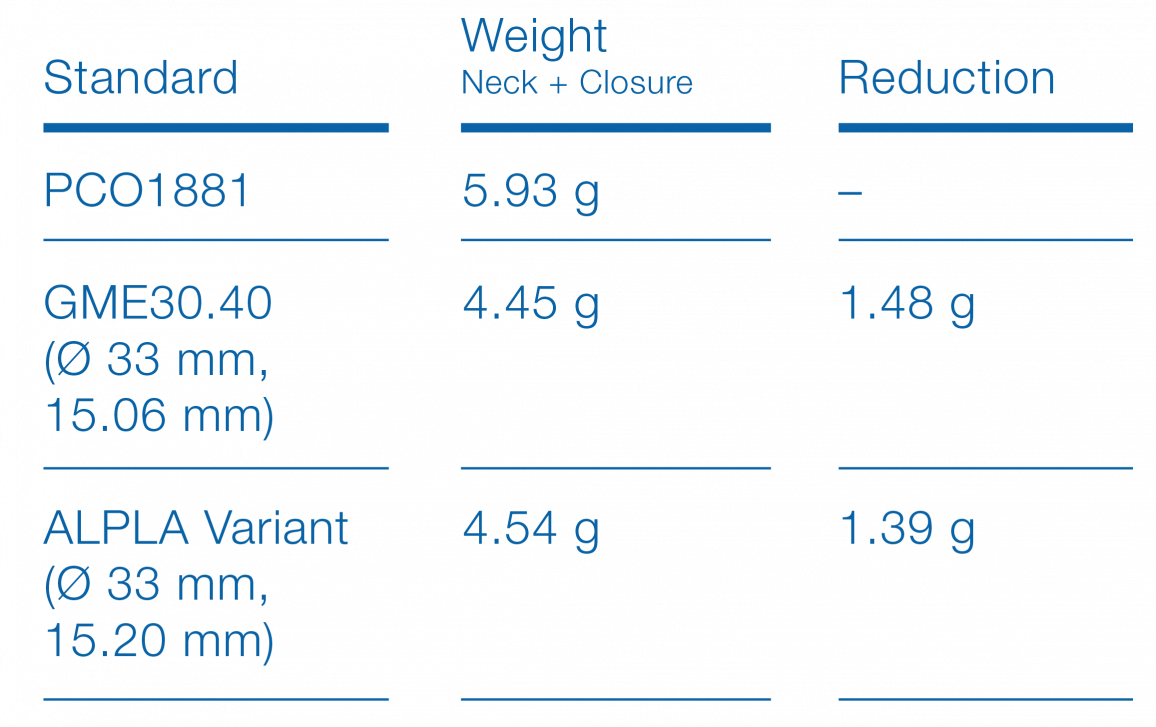

The first bottles with a tethered cap are already in circulation in the German market. They use a variant of the GME30.40 standard, although they have a neck ring of 33 mm and neck height of 15.2 mm. The GME30.40 standard was optimised especially for tethered caps, whereas GME30.37 is more difficult to create as a tethered variant.

Neck ring as a key element

The GME30.40 standard would also allow smaller neck rings with a diameter of up to 30.2 mm and lower neck heights, which would result in much lighter bottlenecks overall. However, this is not always achievable for large bottles. The filling lines and moulds that are currently operated using the old PCO 1810 and 1881 standards would need to be remodelled at high cost. Both of these old standards had a neck ring of 33 mm diameter, and a neck ring of this size allows larger bottles.

Andreas Kainz, Packaging Manager at ALPLA, states, ‘The variant of the GME30.40 that is now on the market combines a great number of benefits. Although it is not the lightest solution, we too recommend this 2.8 g bottleneck to our customers. It is about 1 g lighter than the older PCO 1881 standard, and even 1.4 g lighter when you include the cap. For many companies, 33 mm is also easy to integrate into operations.’

ALPLA variant of the GME30.40

Neck height as a key element

The Cetie recommendation and the variants available on the market also differ in terms of neck height. While Cetie recommends a neck that is 15.06 mm high, many market stakeholders use a slightly higher neck of 15.2 mm, which increases the product safety and suits the new tethered cap better. ‘That is why ALPLA also recommends a neck height of 15.2 mm in this context,’ says Kainz.

All market stakeholders are aware that the construction, retrofitting and remodelling of moulds, filling lines and cappers will be an enormous burden for the industry, so it is very likely that they are interested in having a consistent, established standard as soon as possible. If that does not happen, all the benefits of a free market and competition disappear, because having many different isolated solutions usually has bad impacts on all market stakeholders, financially as well as environmentally.

Under the directive, EU member states are required to ensure by 3 July 2024 that single-use plastic beverage bottles with a capacity of up to three litres are only placed on the market when the cap remains attached to the product during the product’s intended period of usage. This deadline makes it clear that manufacturers cannot delay their decision until the last moment. Creating new moulds and retrofitting and remodelling old ones takes a large amount of time. All stakeholders need to make the switch simultaneously, although many are still waiting to see which variant will be dominant in the end. With every month that goes by without a solution, it becomes more unlikely that European markets will be able to switch in time.

Media

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!