ALPLA and KHS present innovative reusable PET bottle

ALPLA has further developed a 1-litre reusable PET bottle together with KHS, the specialist for bottling and packaging systems. The refillable bottle weighs up to ten grams less than the standard bottles that are currently available and can include recycled materials too.

The life cycle assessment of packaging types in Austria which was presented in April 2019 delivered some informative findings. Roland Fehringer’s independent consultancy company c7-consult took a close look at the environmental impacts of packaging types made of plastic, glass, metal and carton for various product groups. In the area of mineral water, for example, the life cycle assessment examined single-use and reusable bottles made of PET both with and without recycled materials and also single-use and reusable bottles made of glass. The data clearly illustrates that weight, the ratio of packaging weight to the contents, shipment distances and the proportion of recycled materials used have a bearing on the environmental impacts.

From theory to practice

In the product category of mineral water, the theoretical winner of the study was the reusable PET bottle made entirely of recycled materials. It was the winner in theory only, as this packaging solution did not actually exist within the Austrian market when the study was presented in April 2019. At the time, Christoph Hoffmann, Director Corporate Strategy, Sustainability & Circular Economy at ALPLA, made the following statement: ‘We will focus more on reusable systems in the future and will develop practicable solutions in close cooperation with our customers.’

On the one hand, the data for other European countries showed very similar results and lent weight to this project. But on the other hand, innovative solutions for plastic reusable bottles were in short supply due to a declining reusables quota in German-speaking countries. It was therefore evident that there was room for improvement here. And ALPLA wanted to harness this potential together with its innovative partner KHS. This company has more than 20 years of experience in the area of preform and bottle design for reusable PET solutions.

Exclusive partnership with many advantages

ALPLA had already successfully performed sampling for a new reusable solution made of PET at the beginning of this year, in other words eight months after the study was presented. An optimised reusable bottle was then developed in close cooperation with the global KHS Group. ALPLA produces the preforms, which are then stretched, blown and subsequently filled on the KHS production lines.

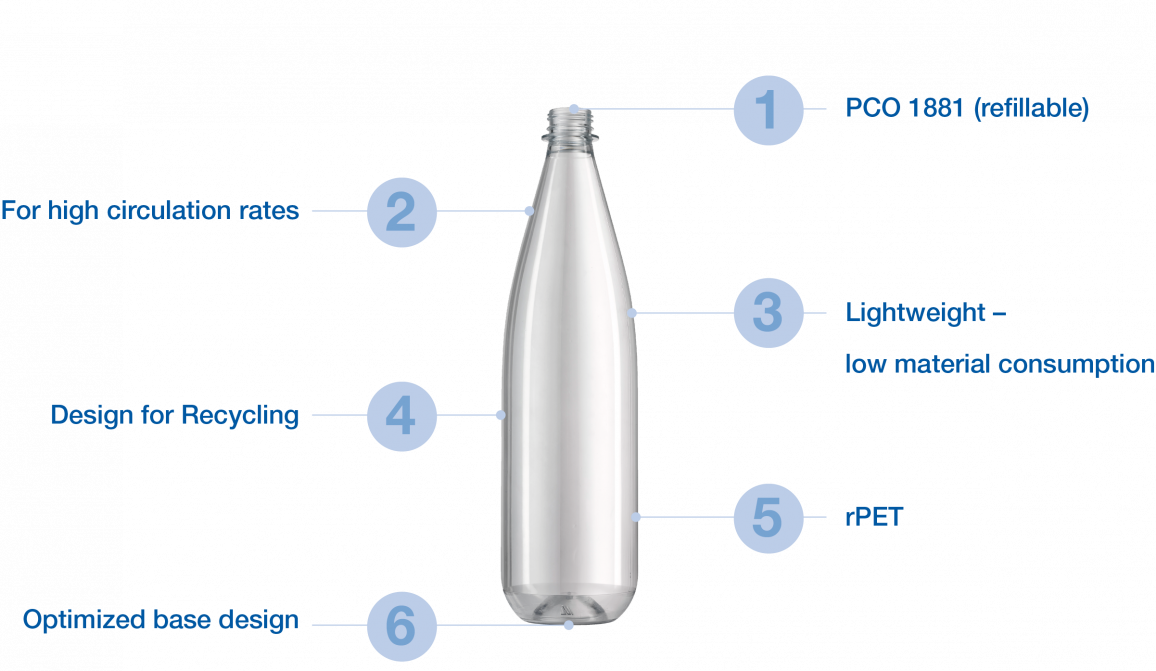

The lightweight among reusable packaging units

Collaboration with KHS ensures that the bottles are ideally adapted to the bottling and washing systems. This is a major advantage when it comes to production processes. The new bottle design also boasts neck and base optimisations that allow for a significant reduction in weight. The bottle weighs a mere 55 grams, and the ALPLA experts say further reductions can realistically be achieved. As a comparison, standard reusable plastic bottles weigh around 65 grams, while reusable glass bottles can even be as much as 550 grams – in other words, ten times the weight of their plastic counterpart.

The bottle is designed with a high circulation rate in mind, in spite of its minimal material usage. The material has to be adequately alkali-resistant in order to maintain the quality and the look of the bottle even after multiple washing cycles. The ALPLA experts additionally took the use of recycled materials into account from the outset when developing this packaging solution. Even when the bottle is withdrawn at the end of its life cycle, it can be recycled and the material can be turned into new PET bottles. Overall, this innovative 1-litre reusable PET bottle takes into account the three principles of the ‘reduce, reuse and recycle’ waste hierarchy.

This joint project with KHS demonstrates once again that there is nothing standing in the way of anyone who earnestly wishes to identify and realise sustainable solutions which are in the interests of the circular economy. The technological possibilities exist. Nevertheless, the packaging should always be adapted precisely to the product and to the market. We recommend you talk to our ALPLA experts to determine whether a reusable or a single-use solution is more suitable for your project.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!