New dimensions and bold decisions: ALPLA 1985-1991

Part four of the Series 70 years of ALPLA: In the middle of the 1980s, ALPLA entered a phase that was to become trend-setting in many respects. The years 1985 to 1991 are characterised by technological leaps, courageous expansion, new markets and a social dynamic that has a lasting impact on the company.

The ALPLA plant in Lübeck is located on the River Trave, around 20 kilometres from where it flows into the Baltic Sea.

First in-house plant in Italy

The year 1985 marks an important strategic step for ALPLA: the first in-house plant for Henkel is built in Lomazzo. The decision to produce directly on the customer's premises changed the co-operation in the long term. Coordination now takes place daily and without detours, delivery times are drastically reduced and technical adjustments can be implemented immediately. Customers benefit from a new level of flexibility and reliability, while ALPLA gains a deeper understanding of local needs and processes. The success of this location quickly confirms the added value of the model and marks the start of a phase in which ALPLA not only expands its international presence, but also aligns it more closely with its customers' locations.

ALPLA sets up the first in-house plant in its history for Henkel.

The step into the digital age

In the mid-1980s, technical modernisation began at ALPLA, which noticeably changed the work in design and production. In 1987, a dedicated computer room was set up at the Steinabrückl plant and the designers switched from the drawing board to 3D CAD technology. Development times are significantly reduced and more complex shapes can be realised more precisely. This is followed shortly afterwards by the introduction of CAM systems that transfer design data directly to modern CNC milling machines. This technological progress gave ALPLA a clear head start, which had a significant impact on developments in the following years.

The next generation of leaders

In parallel, an extraordinary opportunity opened up for ALPLA in the German market. The Schmalbach Group, a direct competitor with strong links to the consumer goods industry and major brands such as Beiersdorf, decides to divest its plastics division in order to focus entirely on can production. This move is highly attractive for ALPLA: taking over the plant in Lübeck gives the company direct access to well-known customers and significantly strengthens its position in the strategically important German market.

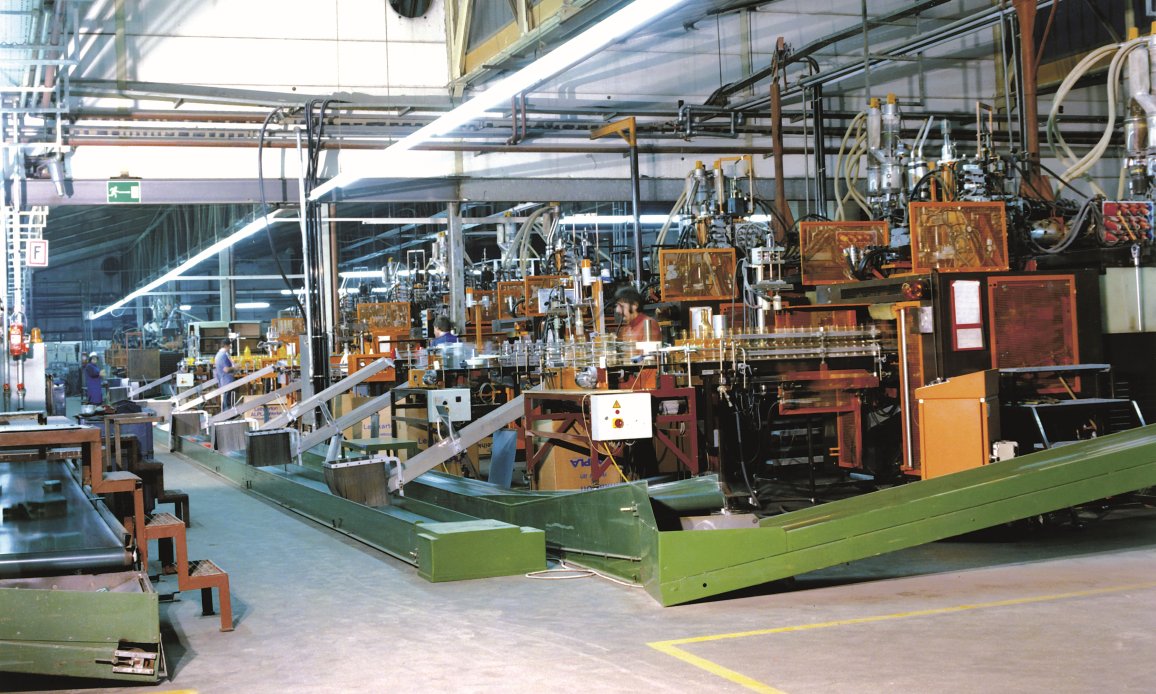

In 1987, Günther Lehner takes over the management of the plant in Lübeck. He was faced with the task of modernising the entire machine park - a feat that was accomplished within a year and won over international customers such as Colgate, Unilever and Beiersdorf. "With the takeover of Schmalbach-Lubeca, we made a leap forward in Europe," Günther Lehner is convinced in retrospect.

In the same year, Georg Früh also starts at the Markdorf plant after completing his business studies and three years in industry in Vorarlberg. Working closely with Helmut Scheffknecht, he learnt all about the company and soon took on important commercial tasks. One of his most formative achievements during this time was the introduction of a standardised, modern accounting system for the entire Group.

New Technical Centre

Technological progress and increasing space requirements lead to the opening of the new Technical Centre in Mockenstraße in Hard in 1988, not far from the headquarters in Lobachstraße. The complex comprises a modern office building and a 4,300 square metre hall for toolmaking, special machine construction and plant engineering.

For the first time, all central technical areas work together at one location. Processes are faster, coordination is more direct and repairs and developments are better integrated. The Technical Centre will be a visible sign of the company's commitment to innovation.

An important step for ALPLA: the construction of the Technical Centre in 1988.

Political upheaval and new markets

While ALPLA is repositioning itself technologically, the geopolitical environment is also changing dramatically. The fall of the Berlin Wall in November 1989 and the dissolution of the Eastern Bloc opened up new economic prospects. Employees in Lübeck, just a few kilometres from the former border, experience these historic events at first hand. The Steinabrückl plant is also located in the immediate vicinity of Hungary, which quickly opens up and reorients itself economically.

This dynamic creates a decisive opportunity: market entry in Eastern Europe. As early as 1990, ALPLA starts production in Tatabánya, Hungary, in a technologically significant area. The first PET beverage bottles for Coca-Cola are produced here, at a time when PET technology is just about to conquer the beverage market. From Hungary, a growing network of other sites in Poland and the Czech Republic developed over the following years.

First step into Mexico

Almost parallel to the developments in Europe, another door opened on another continent. The successful collaboration with Johnson Wax in Venezuela led ALPLA to explore the Mexican market for the first time in the early 1990s. The assessment is quickly clear: there is enormous potential here.

In 1990, the first plant is built on Mexican soil in Toluca, not far from the airport. It is the 22nd ALPLA plant and also the third overseas location. With this step, the company expands its presence on the American continent and lays the foundation for future growth in North and Central America.

The first ALPLA plant on Mexican soil in Toluca.

Environmental awareness and new materials

In parallel with the international changes, the environment is becoming increasingly important. Forest dieback, smog and energy crises are raising public awareness of ecological issues and ALPLA is reacting early. Heat recovery systems are installed in all European plants to significantly reduce energy requirements. At the same time, the company is focussing on new materials and advanced technologies. The two-layer bottle for NIVEA from 1988 is a success, followed in 1990 by a particularly innovative 1000-millilitre multi-layer bottle for Lenor fabric softener. The special thing about it is that it is made from 25 per cent recycled material, paving the way for further developments in this area.

This marks the end of a phase in which ALPLA reaches new dimensions in terms of technology, organisation and geography, paving the way for the global development of the 1990s.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!