Sustainability report: ALPLA increasingly focusing on a circular economy

The fourth sustainability report prepared by ALPLA, the global specialist for innovative packaging solutions and recycling, illustrates the progress the company made in the area of sustainable development between 2018 and 2020.

CEO Philipp Lehner and Christoph Hoffmann, Director of Corporate Strategy, Sustainability & Circular Economy, with the sustainability report 2020.

In its latest sustainability report entitled ‘The cycle to a better future begins with the right packaging’, ALPLA gives an extensive update on the topic of sustainability and the company’s targets. CEO Philipp Lehner sets out the key aspects of the strategy for the next few years: ‘I believe that ALPLA as a company has a responsibility towards society to guarantee secure, affordable and sustainable supplies for the global population in the future too. At the same time, with a carbon footprint which is usually lower than that of alternative packaging solutions, plastic makes an important contribution to climate protection.’

Circular economy as a success factor

The circular economy has been an important part of ALPLA’s sustainability strategy for many years, with the company always championing closed loops and greater awareness of plastic as a recyclable material. After all, the use of recycled plastics conserves fossil resources and reduces carbon emissions. For example, PET regrind material from the ALPLA plants in Austria and Poland causes up to 90 per cent fewer greenhouse gas emissions than virgin material. With input of around 206,000 tonnes of PET and approximately 88,000 tonnes of HDPE, ALPLA’s own recycling plants and joint ventures around the world are, in total, contributing significantly to the use of recycled plastics in production.

Expansion of renewable energy

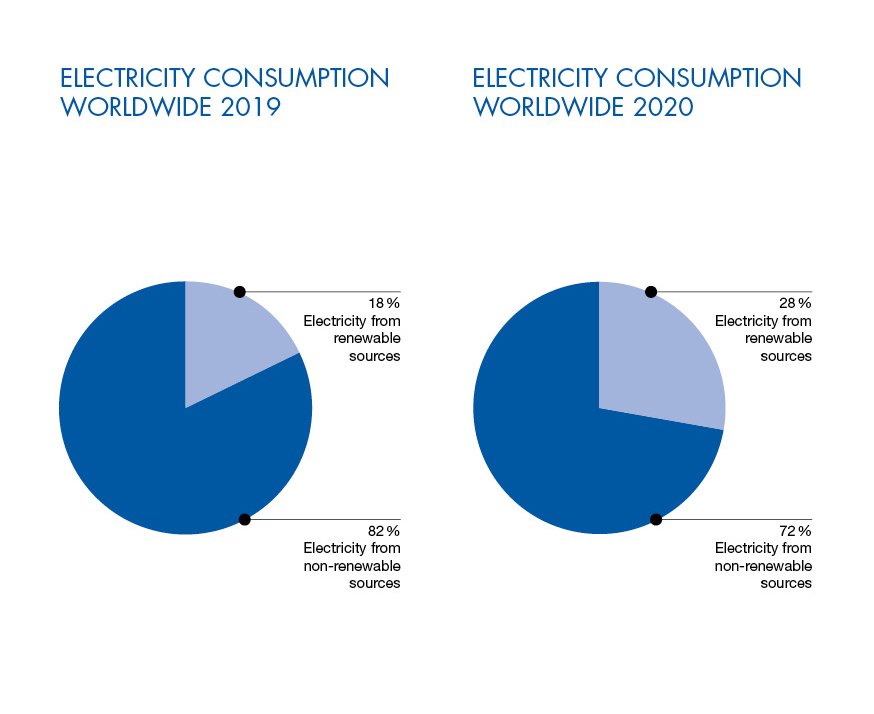

Electricity accounts for around 95 per cent of ALPLA’s total energy consumption. The company therefore sets great store by the efficient and responsible use of electricity. In addition to using cutting-edge technologies, a key topic is increasing the proportion of electricity from renewable sources: ‘Globally speaking, we were already covering 28 per cent of our electrical energy consumption with electricity from renewable sources in 2020, compared with 18 per cent in 2019,’ says Martin Stark, Director of Corporate Plant Engineering, giving an insight into the current developments.

Focus on the employees

At ALPLA, the focus is always on people. The safety, good health and equal treatment of the 21,600 employees around the world are top priorities. ALPLA also sets great store by continuing professional development, employee development and training up a new generation of workers in its training workshops.

The ALPLA Sustainability Award was initiated this year to train a spotlight on the huge commitment to sustainability demonstrated by the employees on a daily basis. This involved projects in the areas of recycling and waste reduction, the protection of local ecosystems, and social issues being submitted and recognised.

In-house plants cut carbon emissions

In terms of production, it is important to ALPLA that it acts locally. In 2020, 68 of its 178 sites were operated as in-house plants. Around 42,500 tonnes of carbon emissions were saved in 2020 by locating packaging production wall-to-wall with the customers’ bottling lines, thus eliminating transport journeys.

Growth in various regions

In addition to the Asia region (China, South East Asia and India), the AMET region (Africa, Middle East and Turkey) in particular is one of ALPLA’s strongest growth regions. Encouragingly, the topic of sustainability is gaining in importance in this region. Christoph Hoffmann, Director of Corporate Strategy, Sustainability & Circular Economy, has the following to say on the current developments: ‘We are anticipating strong growth in the AMET region in particular, specifically in Africa. The task in hand is to now implement the recycling and waste management solutions which have been in place in Europe for some time in these regions too.’

Media

Press contact

ALPLA

Lukas Österle

Senior Sustainability Communications Manager

+43 5574 602 2132