ALPLA starts production at the new plant in Lanseria near Johannesburg

In the presence of the South African Environment Minister, the ALPLA Group opened a state-of-the-art production site in Lanseria near Johannesburg. In the new headquarters for Sub-Saharan Africa, the internationally active plastic packaging specialist is merging five previous locations in South Africa under one roof. All ALPLA technologies, processes and materials are combined in the Lanseria plant and the first apprenticeship programme of ALPLA in Africa will start at the beginning of 2023.

Important visitors at the opening of ALPLA’s new headquarters for Sub-Saharan Africa in Lanseria on 12 October: ALPLA CEO Philipp Lehner welcomed the South African Environment Minister Barbara Creecy and the Premier of Gauteng Panyaza Lesufi.

35,000 square metres of covered production, administration and storage space, another 12,500 for future expansion, and 30,000 square metres of roof area equipped with solar panels: with the new plant in Lanseria, ALPLA is setting the course for further growth in Sub-Saharan Africa. After around two years of construction and relocation, the international packaging company celebrated the opening of the ultra-modern location on 12 October in the presence of the South African Minister of Forestry, Fisheries and the Environment Barbara Creecy, the Premier of the Gauteng province Panyaza Lesufi, the Austrian Ambassador-Designate to South Africa Romana Königsbrun and many other high-ranking guests.

The international packaging specialist ALPLA is merging its activities in South Africa and starting production in the new ultra-modern plant in Lanseria near Johannesburg.

‘All of Sub-Saharan Africa is on the upswing, the markets have enormous potential. Our investment in South Africa is a clear commitment to the continent. In this way, we are increasing our competitiveness and guaranteeing the long-term regional supply of safe, affordable and sustainable packaging solutions,’ explains ALPLA CEO Philipp Lehner. ‘Here in Lanseria we concentrate our expertise, optimise production processes, use state-of-the-art equipment and create energy-efficient operations,’ adds Mike Resnicek, Managing Director Sub-Saharan Africa at ALPLA. The plant has one of the largest solar installations on a privately owned manufacturing building in South Africa.

At the new plant in Lanseria, ALPLA uses state-of-the-art technology and machinery to produce high-quality bottles, closures and special packaging – around 3.5 billion units per year in total.

Combined competencies and technologies

The new location in the industrial area north of Johannesburg combines and builds on the five previous plants in Harrismith, Denver, Isando, Kempton Park and Samrand. The departments, employees and machines were relocated step by step. Around 350 employees will start working in Lanseria and their number is subject to further growth. The new plant will produce bottles, closures and special packaging for the food, personal and home care, chemical, cleaning agent and pharmaceutical industries – a total of around 3.5 billion pieces per year.

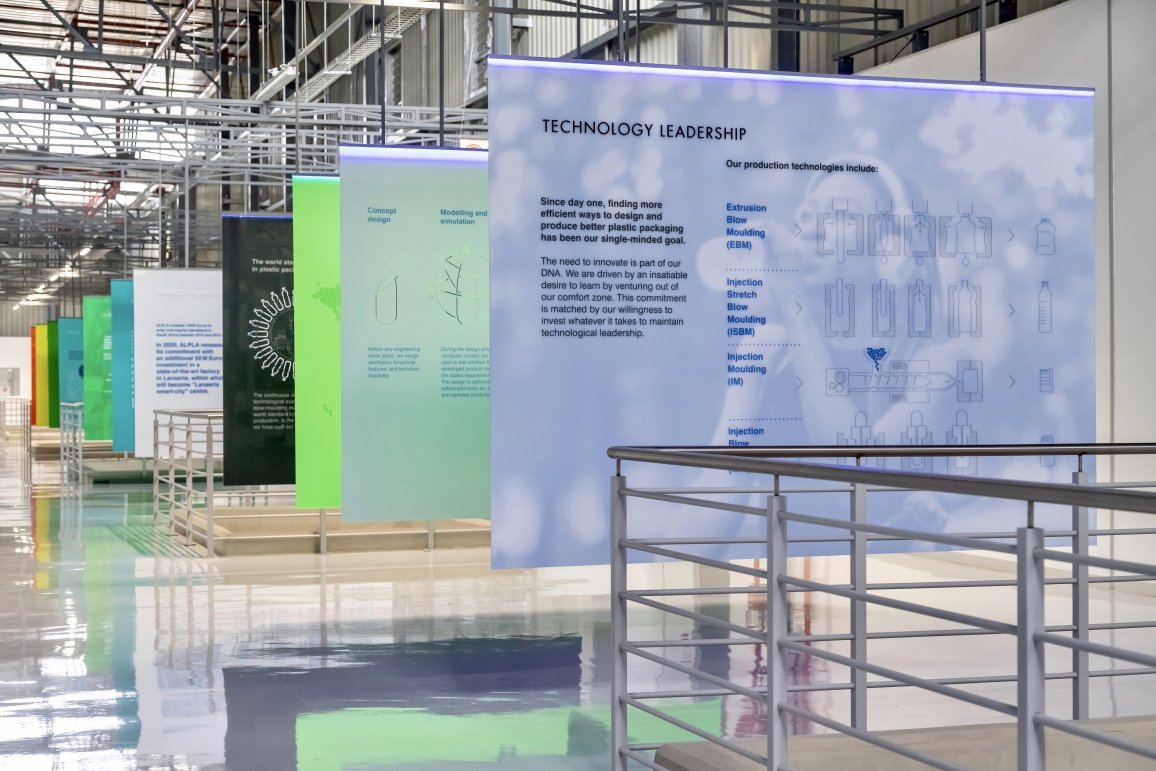

ALPLA uses six different technologies, including injection and compression moulding, injection stretch blow moulding and extrusion blow moulding. In addition to international corporations, ALPLA also supplies smaller local companies with plastic packaging solutions. ‘The new plant with its modern equipment meets all international quality standards, is operated efficiently and increases flexibility. Our customers in the region will benefit from this service in the long term,’ says Javier Delgado, ALPLA Regional Managing Director Africa, Middle East and Turkey.

Around 350 employees will start working in Lanseria and their number is subject to further growth.

Success story apprenticeship

With the new plant in Lanseria, ALPLA is also promoting its own training of specialists and has established a dual education and apprenticeship programme. This dual system of practical and theoretical training based on the Austrian model is already in operation at the ALPLA locations in Germany, Mexico, India, Poland and China. From 2023, the first 12 South African apprentices are to begin their training in the plastics technology and machining technology trades in the ‘Future Corner’ training centre in Lanseria.

Independent personnel development is an important building block for the future of the company, as Resnicek emphasises: ‘Global know-how, ability to run on state-of-the-art equipment, innovative spirit, team spirit and problem-solving skills characterise our “Family of Pioneers”. We introduce young people, mainly from the Lanseria community, to the world of ALPLA and offer them the opportunity for professional and personal development. We look forward to the African and South African premiere of this successful model.’

In addition to information on the business segments and technologies, the ALPLA Skywalk offers insights into the history of the internationally active packaging and recycling company.