‘Lightweighting’: a Diet for Packaging

Packaging plays an important role in the goods we use in our daily lives. For example, it facilitates the transport of products and protects food from spoiling, so we can enjoy it for longer. Good packaging can actually keep prices down, since it reduces the cost of transport, distribution, storage, retailing and all types of food wastage. The optimisation of packaging certainly is a continuous and never-ending process. An important part of this process is the optimisation of resources.

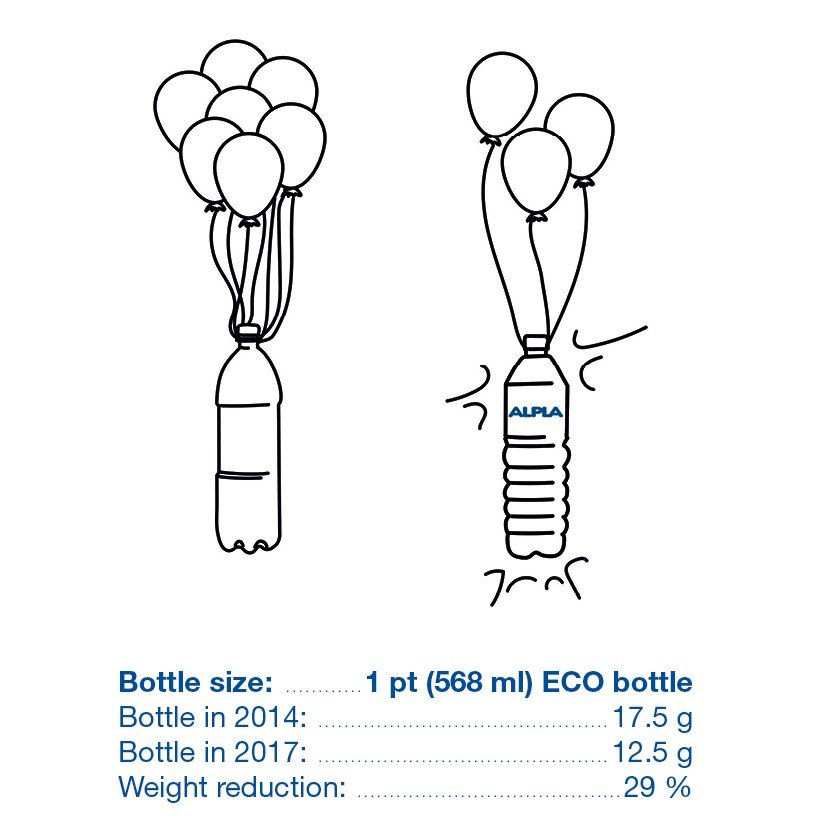

Manufacturers try to follow the motto ‘less is more’. Packaging is becoming lighter and lighter. It is made lighter to the point that, although we can find more packaged goods nowadays, the total weight of material being used for the production of packaging has reduced consistently over the last 20 years. For example, an already lightweight milk bottle developed by ALPLA weighed 5 grams less in 2017 than in 2014.

There is more than one reason for the effort manufacturers put into ‘lightweighting’. One aspect is surely an economical one. Of course, lighter packaging means less material is used, which saves costs. However, the environmental aspect is significant as well. Even the smallest reduction in the amount of plastic used for a product can significantly decrease the strain on our environment.

The Challenges

Considering the benefits of lightweighting, there is really no reason not to decrease the weight of packaging further and further; but unfortunately, lightweighting brings its challenges along with it. While saving costs and creating a more sustainable solution, the functionality of the packaging has to be kept in mind as well. You have to be careful not to design a solution which is too flimsy for transport or labelling. Also, lightweighting should not be driven to the point of losing the advantage of increased sustainability. If the material is too thin, the bottles might need a protective layer of nylon or an oxygen scavenger to create a barrier that preserves the product, which could then contaminate the recycling stream.

There are several obstacles manufacturers might hit during the process of designing a lighter bottle. Design is critical and each material type has its own challenges. For example, one of the first issues in PET bottle manufacture starts at the preform and bottle design stage. The preform needs to be designed to allow the bottle to be safely blow moulded, meaning the preform and the bottle design have to be compatible with each other. If the preform is too long, for example, the base and the shoulder weight are too high, which means material has to be saved elsewhere. Other types of plastics (polymers) need different production techniques, such as extrusion blow moulding, which come with their own challenges as well. For example, the wall thickness and material distribution to ensure the functional and performance requirements despite the weight reduction.

It is also important to consider the filling operations of the packaging. If the bottles are filled using ‘Jet Stream’ air systems which work with neck handling, then the bottles must have a special space below the lowest part of the neck to transport the bottles in these specialised transport systems. Of course, the bottle will most certainly need a label as well. For the labelling, a certain stability of the bottle needs to be ensured. Generally, if you label the bottle after filling it, it will be more stable and easier to label. If the bottle is labelled before filling, it is more flexible, making labelling more difficult, especially when the bottle is lightweight. Other disadvantages of labelling after filling can be that the bottle might get wet on the outside, which would also make labelling more difficult. The label material type must also be kept in mind: if the material used is not recyclable, the environmental advantage of lightweighting is diminished.

These are just some of the issues and ones which must be considered with the customer, their marketing departments and consumers – and all aspects must be considered during the design of a bottle, especially when the goal is to decrease weight. While lightweighting brings economic and environmental benefits, it is important to not lose the functionality of the bottle.

Our Lightweighting Project

In 2014, we received the challenging task of designing a bottle for the dairy market. The goal was a 20 per cent lighter bottle than the average current products sold on the market. An added challenge was to also increase the content of food-approved post-consumer recycling material (rHDPE) within the bottles. This lightweighting challenge involved Packaging Managers, Product Designers, Logistical Equipment Designers and Programme Managers who had to tackle all of the above-mentioned issues and more to achieve the goal. At the end of the design and development process, we had created the ALPLA Eco-Bottle Range. ALPLA’s Eco-Bottle Range successfully combines the economic savings, the environmental benefits and functionality requirements of the bottles. The Eco-Bottle has established itself in this market sector and is used by many customers with the majority share of the UK dairy market.

As technology continues to advance, we’ll have to wait and see how far lightweighting can go. Statistics show that consumers in Europe are increasingly concerned with the impact of plastics on our ecosystems. All the more reason to use less material, along with other activities such as recycling of materials. In the end, the ultimate solution must use sufficient resources to make sure products and food are protected from production to consumption, offering the customers and consumers what they require while minimising the impact on the environment. By doing all of this, you’ll successfully create a functional and sustainable product.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!