Caps with added value: sustainable packaging solutions

ALPLA plant in Föritztal: specializing in eco-friendly caps

The ALPLA plant in Föritztal in Germany specialises in cap development. Since 2020, our experts have been creating innovative caps. We are offering an insight into two exceptional projects.

David Martin, Maik Göpfert and Justin Maaser (left to right) during a meeting inside the Foeritztal plant.

Glass bottles don’t actually exist in the world of ALPLA. But even glass bottles need the right cap. It should ideally be light, practical and sustainable. Which is where the plastics experts come into play. Föritztal Plant Manager Maik Göpfert sees a huge opportunity here: ‘If we think outside the box and offer optimum caps for third-party containers, we will acquire new customers and develop market segments.’

25 projects on-site of sustainable cap development

The internal Development department was established in 2020. Since then, Project Managers David Martin and Justin Maaser have realised numerous projects and caps on-site. There are currently 25 projects. Every injection-moulded part aims to generate added value focusing on reduced weight, an optimised shapes and enhanced recyclability. ‘We are focusing on regional customers. There is high demand and it continues to increase,’ says a delighted Maik Göpfert. Things are therefore looking good for the plant, which is celebrating its 30th anniversary this year. So there is a good chance that sparkling wine corks they produced themselves will be popping at the party.

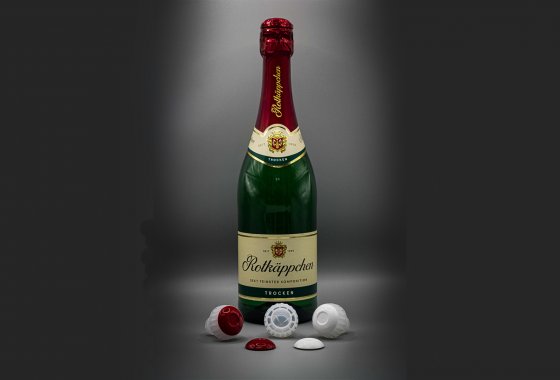

Sparkling success: sustainable wine corks for Rotkäppchen-Mumm

ALPLA's Collaboration with Rotkäppchen-Mumm

Rotkäppchen-Mumm, the market leader in sparkling wine and spirits, is committed to sustainability, focusing on lighter glass bottles, increasing its recycling rate and sourcing materials by rail. There was still more potential in the plastic cork and the company first approached ALPLA in early 2020. ‘Developing a cap independently of a bottle was new territory for us,’ remembers Project Manager David Martin.

ALPLA's Collaboration with Rotkäppchen-Mumm

Rotkäppchen-Mumm, a market leader in sparkling wine, partnered with ALPLA in 2020 to create sustainable sparkling wine corks. Project Manager David Martin recalls this innovative challenge: developing a cap independently of a bottle. Because sparkling wine caps are forced in rather than screwed on, they have to be able to withstand internal pressure. In addition, the cork is made of two parts – an injection moulding challenge.

Key Features of Sparkling Wine Corks

The plastic cork with a famous red cap ('Rotkäppchen' means 'little red cap' translated into German) is made of HDPE. While the stopper is made of softer LDPE balances out the internal pressure up to 10 bar for two years. Achieving a ten percent weight reduction was a triumph for sustainability, setting a new standard in the industry. Giving no deterioration in quality or mechanical losses.

Currently producing 70 million corks annually, ALPLA continues to explore closure systems made from recycled or bio-based materials. ‘This showpiece product for the market leader is our entry ticket,’ says Martin, delighted.

Elderly-friendly innovation: easy-to-open mineral water caps

ALPLA addresses the needs of elderly consumers

A convenient cap for reusable glass bottles which is suitable for the elderly was the aim of a project managed by Justin Maaser in 2019. Elderly consumers of mineral water repeatedly complained about difficulties with opening glass bottles. Following a number of simulations, the Foeritztal plant succeeded in developing a very easy-grip cap. ‘It’s easy to open, but it nevertheless closes securely and robustly,’ explains Maaser.

Hand-friendly caps across germany

Since April, numerous reusable glass bottles in Germany feature these hand-friendly caps. There is huge potential of up to 4.5 billion caps a year in Germany alone. ‘With this practical cap, we are making life easier for many people,’ says Maaser with conviction. The establishment of the Development department proves its worth, with 500 million caps expected in the first year alone.

Do you like our texts? Perhaps even so much that you want to use them in your own media? Then please get in touch with us beforehand!